Technologie

Magnetische Seilprüfung:

Modernste Technologie zur zerstörungsfreien Seilinspektion im digitalen Zeitalter.

Seilprüfung 4.0

Die fortschreitende Digitalisierung und die damit einhergehenden technischen Entwicklungen bieten auch bei der zerstörungsfreien Prüfung von Seilen viele neue Vorteile und Möglichkeiten.

Aus jahrelanger Erfahrung in der magnetischen Drahtseilprüfung haben wir ein Gerät entwickelt, das sowohl vielseitige Prüfaufgaben meistert als auch durch präzise Analyse, sichere Datenverarbeitung sowie zuverlässige Seilbeurteilung höchste Sicherheit gewährleistet. Unsere magnetische Seilprüfung bietet außerdem eine präzise Analyse und sorgt deshalb für höchste Sicherheit bei der Prüfung von Seilen.

Präzise und effizient mit magnetischer Seilprüfung

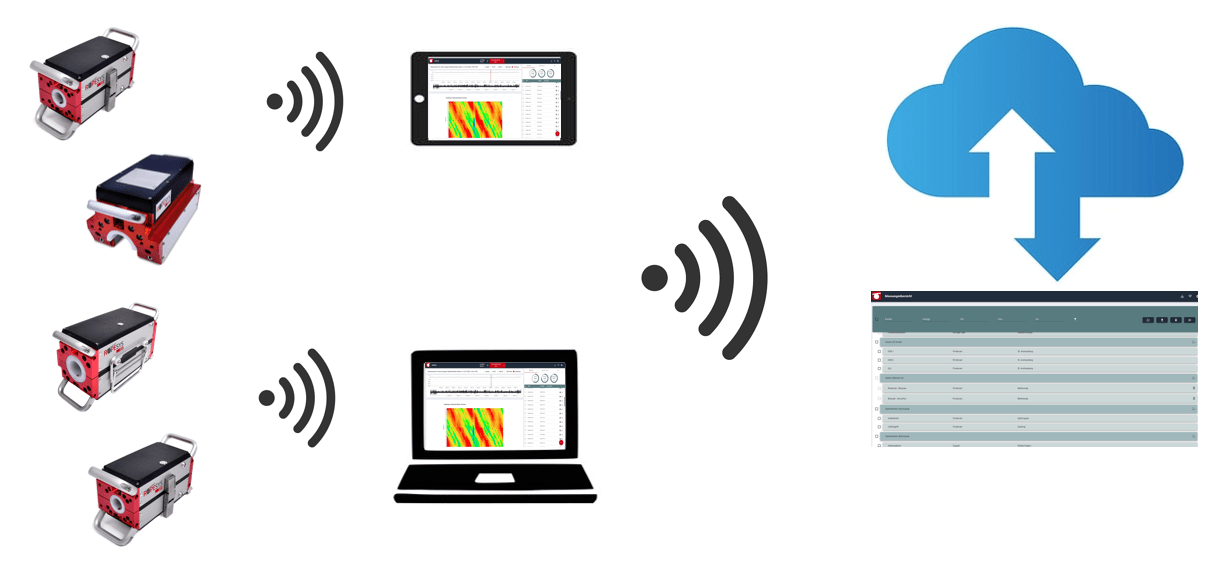

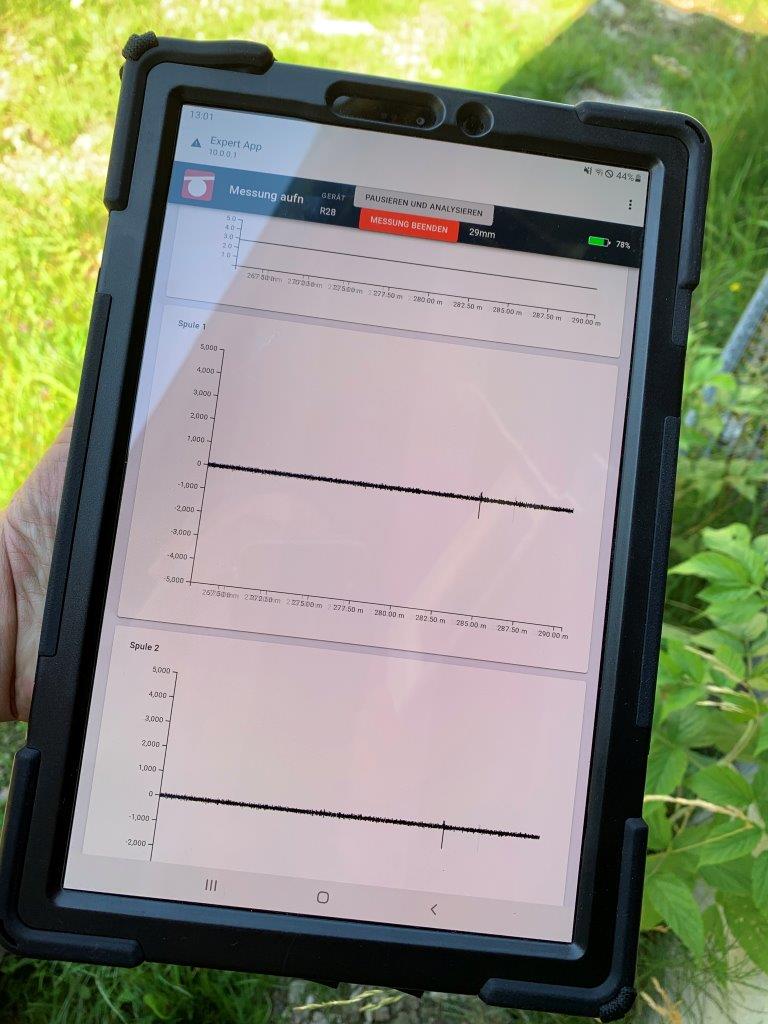

- Die kabellose Bedienung und Visualisierung der Messung ermöglichen eine unterbrechungsfreie Fortführung der Messung, selbst bei Verbindungsabbrüchen. Sobald die Verbindung wiederhergestellt ist, kann die Messung dadurch problemlos fortgesetzt werden.

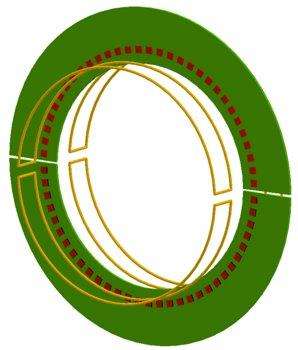

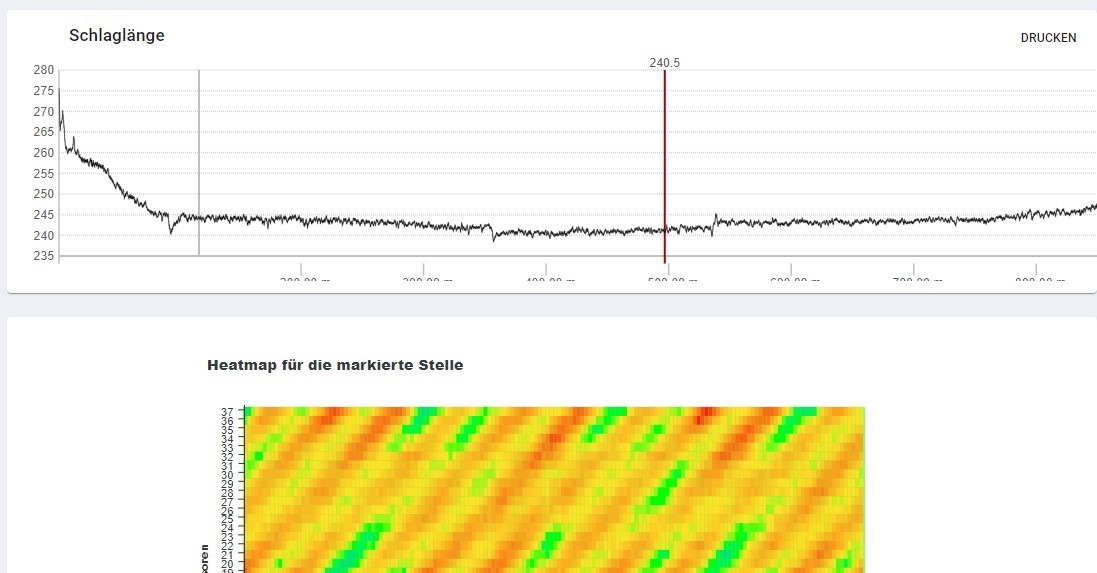

- Das innovative Sensorkonzept besteht aus zwei Induktionsspulen und bis zu 48 Hallsensoren, die direkt im Sensorkopf vorverarbeitet und digitalisiert werden.

- Es stehen sowohl LF- als auch LMA-Signale zur Verfügung.

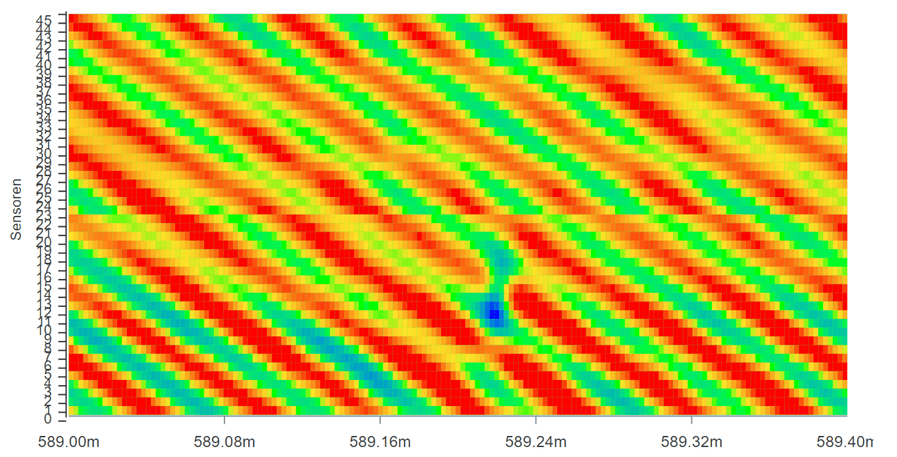

- Die Fehlstellen können außerdem in 3D lokalisiert werden.

- Effizientere Magnettypen sorgen deshalb für eine bessere Leistung als vergleichbare Systeme.

- Außenliegende Kabel wurden außerdem auf ein Minimum reduziert.

- Zusätzlich zum bekannten Expertensystem für Prüfdienstleister gibt es ein automatisiertes „Smart Device“, das den Zustand eines Seils automatisch analysiert und bewertet. Der Benutzer erhält sowohl eine klare als auch verständliche Darstellung des Seilzustands.

Key Features:

- Das datenbankbasierte Ablagesystem für Messungen bietet eine Synchronisierungsoption zwischen den Prüfgeräten und der Auswertetechnik. Dadurch können Messungen direkt auf dem Prüfgerät gespeichert und zu einem späteren Zeitpunkt bequem analysiert werden. Dank dieser Synchronisierung stehen Ihre Daten jederzeit und überall zur Verfügung, was Ihre Prüfprozesse flexibler und effizienter macht.

Flexibilität und Datenzugriff:

- So können Sie Messungen direkt auf dem Prüfgerät speichern und später bequem analysieren. Dies ermöglicht eine schnelle Auswertung der Daten zu jedem Zeitpunkt. Dadurch wird sichergestellt, dass Sie die Messungen nach Belieben überprüfen und die Ergebnisse nach Bedarf weiterverarbeiten können.

- Eine Synchronisierung mit einer zentralen Datenbank ist ebenfalls verfügbar, wodurch die Daten zu einem späteren Zeitpunkt auf einem anderen Rechner analysiert werden können. Dies erleichtert sowohl die Synchronisation als auch die spätere Analyse der Daten erheblich.

- Die Software läuft vollständig auf dem Prüfgerät, wodurch die Bedienung mit jedem internetfähigen Endgerät und einem gängigen Browser möglich ist. Dadurch bleibt die Nutzung besonders einfach und ortsunabhängig. Außerdem lässt sich die magnetische Seilprüfung sowohl schnell als auch flexibel durchführen, unabhängig von Ort oder Gerät.

- Alle gewohnten Editierfunktionen wie Schneiden, Versetzen und weitere sind ebenfalls verfügbar. Darüber hinaus prüft die Software automatisch die Funktionalität der Sensoren. Vor jeder Messung erfolgt ein Selbstcheck, bei dem die Sollwerte direkt auf dem Sensor gespeichert werden, was eine fehlerfreie Messung garantiert. Dank des automatischen Selbstchecks mit direkter Sollwertspeicherung am Sensor können Sie sich auf fehlerfreie Messergebnisse verlassen.“

- Sollte versehentlich ein Sensor mit der falschen Größe eingebaut werden, erkennt die Software dies und informiert sofort, um Fehler zu vermeiden. Dadurch wird sichergestellt, dass sowohl korrekt konfigurierte Sensoren als auch die Genauigkeit der Messung gewährleistet sind, was eine fehlerfreie Analyse garantiert. Somit gewährleisten wir eine hohe Messgenauigkeit und eine zuverlässige Datenanalyse.

Präzision und Qualitätssicherung:

- Die Software führt automatisch eine Normbewertung durch und zeigt den Grad der Ablegereife der Messdaten unmittelbar an, und informiert den Nutzer sofort über den Seilzustand. Auf diese Weise wird eine kontinuierliche Überwachung des Seilzustands gewährleistet, was die Präzision der magnetischen Seilprüfung erhöht.

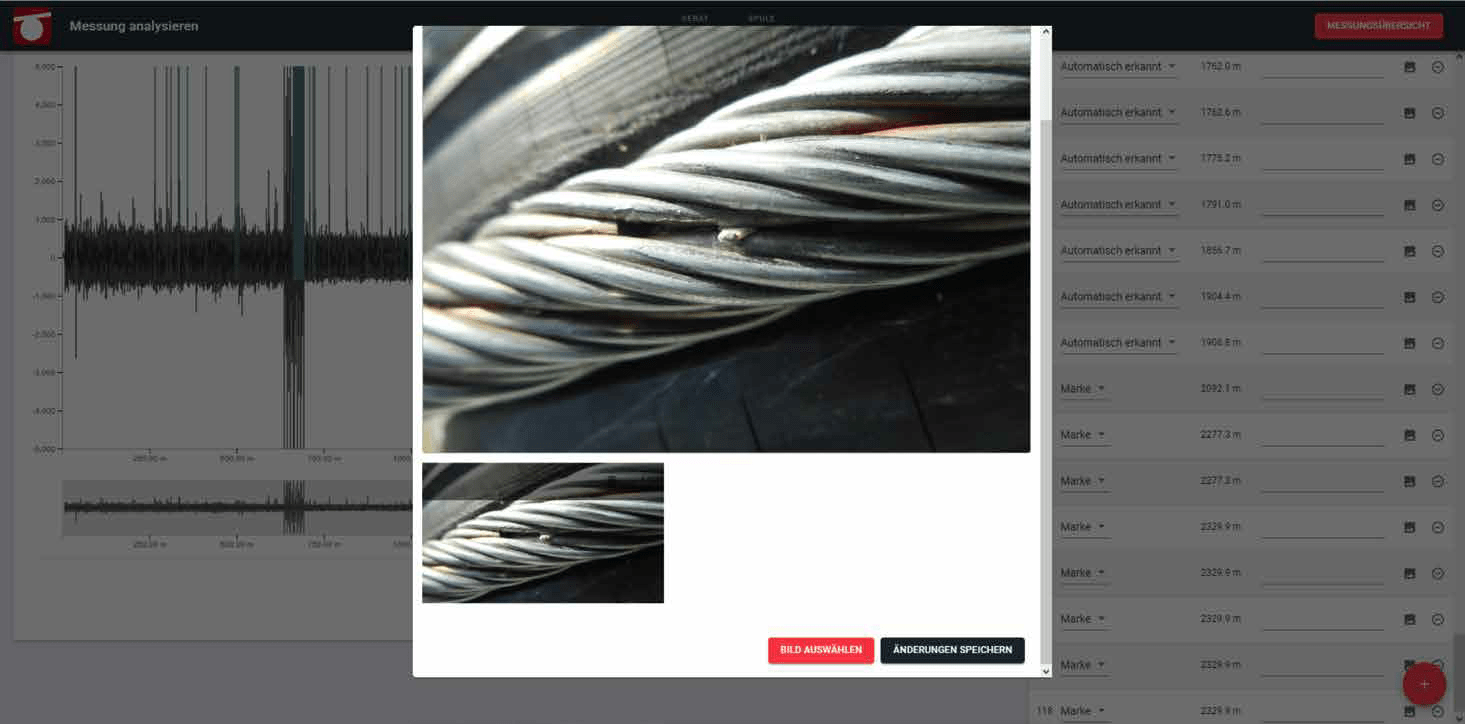

- Die magnetische Seilprüfung wird durch die leistungsstarke Software unterstützt, die eine präzise Analyse der Fehlstellen und des Seilzustands ermöglicht. Darüber hinaus kann der Nutzer zu den ermittelten Fehlstellen neben manuellen Messdaten wie Schlaglänge und Durchmesser auch Fotos hinzufügen und diese direkt mit der entsprechenden Fehlstelle verknüpfen. Dies ermöglicht eine detaillierte Dokumentation und steigert die Genauigkeit der Prüfung.

Umfassende Dokumentation:

- Der Nutzer kann zu den analysierten Daten einen PDF-Bericht erstellen, der nicht nur die Messbedingungen, sondern auch alle Fehlstellen und die Normbewertung enthält. Dadurch erhält der Nutzer eine vollständige Übersicht der Messung, die alle relevanten Informationen übersichtlich darstellt.

- Made in Germany

Die Produktion und der Vertrieb der Seilprüfgeräte erfolgt durch die ROPESYS GmbH in Lizenz ROTEC GmbH.

Die Seilprüfgeräte sind in den ersten Baugrößen erhältlich. Weitere Standard- und Sonder-Baugrößen sind in Planung.

HIER erhalten Sie eine Übersicht über die verschiedenen Geräte und Baugrößen

Fragen beantworten wir Ihnen jederzeit gerne. Die Antworten auf häufige Fragen finden Sie auch in unseren FAQs.

Im Rahmen des zentralen Innovationsprogramms Mittelstand (ZIM) der Arbeitsgemeinschaft industrieller Forschungsvereinigungen „Otto von Guericke“ e.V. (AiF) fördert das Bundesministerium für Wirtschaft und Energie sowohl die ROTEC GmbH als auch die innovative Entwicklung des neuartigen Seilprüfsystems.

Weitere Informationen?

Hier können Sie die aktuelle Broschüre der ROTEC GmbH herunterladen