Technology

State-of-the-art technology for magnetic rope testing in the digital age

Rope testing 4.0

Advancing digitalization and the associated technical developments also offer many new advantages and opportunities in the non-destructive testing of ropes.

Decades of experience in magnetic wire rope testing have resulted in a device concept that meets the requirements of both versatile testing tasks and safe, reliable data processing and rope evaluation.

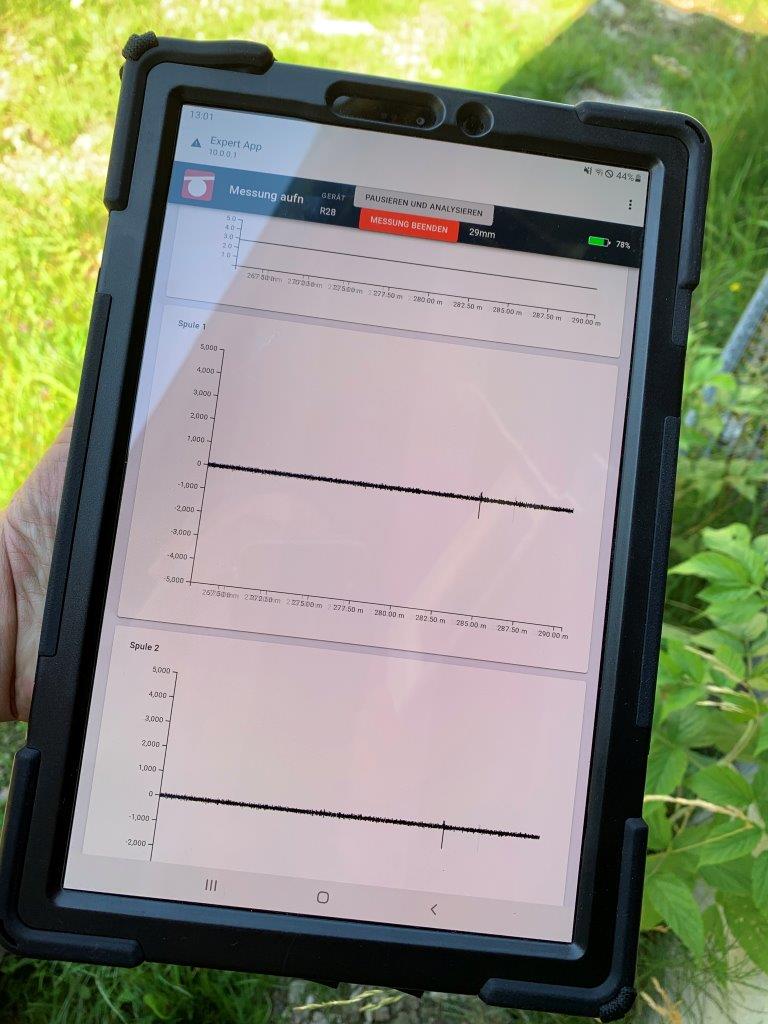

- Wireless operation and visualization of the measurement. The measurement is continued even if the connection is lost and can be operated further when the connection is re-established.

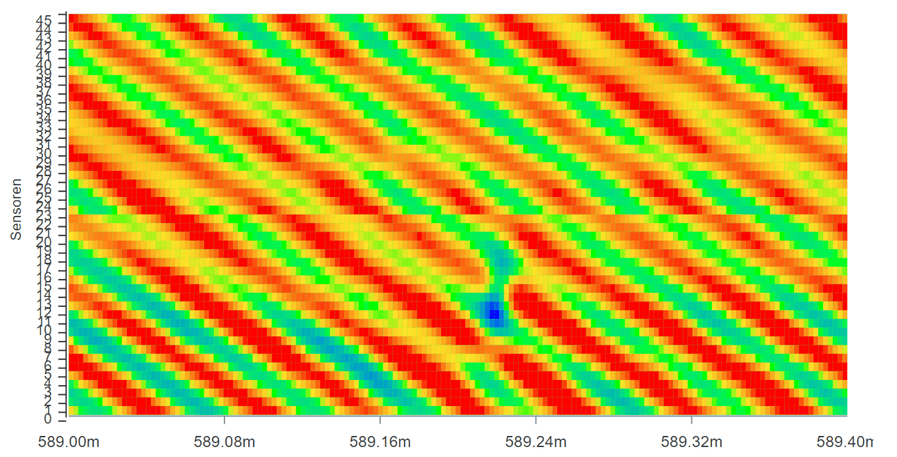

- Innovative sensor concept with 2 induction coils and up to 48 Hall sensors, which are preprocessed and digitized in analog directly in the sensor head.

- LF and LMA signals available.

- 3D localization of the defects possible.

- More efficient magnet types than comparable systems.

- External cables are reduced to a minimum.

- In addition to the well-known expert system for testing service providers, an automated “smart device” is also available, which automatically analyzes and evaluates the condition of a rope. In addition to the well-known expert system for testing service providers, an automated “smart device” is also available, which automatically analyzes and evaluates the condition of a rope.

Key Features:

- Database-based filing system for measurements incl. Synchronization option between test equipment and evaluation technology.

- Measurements can be stored and analyzed on the tester.

- Synchronization with a central database is available and allows convenient analysis of the data at a later time on another computer

- The software runs completely on the tester. The operation is thus possible with any Internet-capable terminal device with a common browser.

- Common editing functions such as trim, offset, etc. are available. The software automatically checks the functionality of the sensors. A self-check is performed before each measurement, with the setpoints stored on the sensor itself. Accidental installation of different sensor sizes is also recognized and

communicated to the user. - The software itself performs a standard evaluation and immediately shows the user the degree of discard maturity.

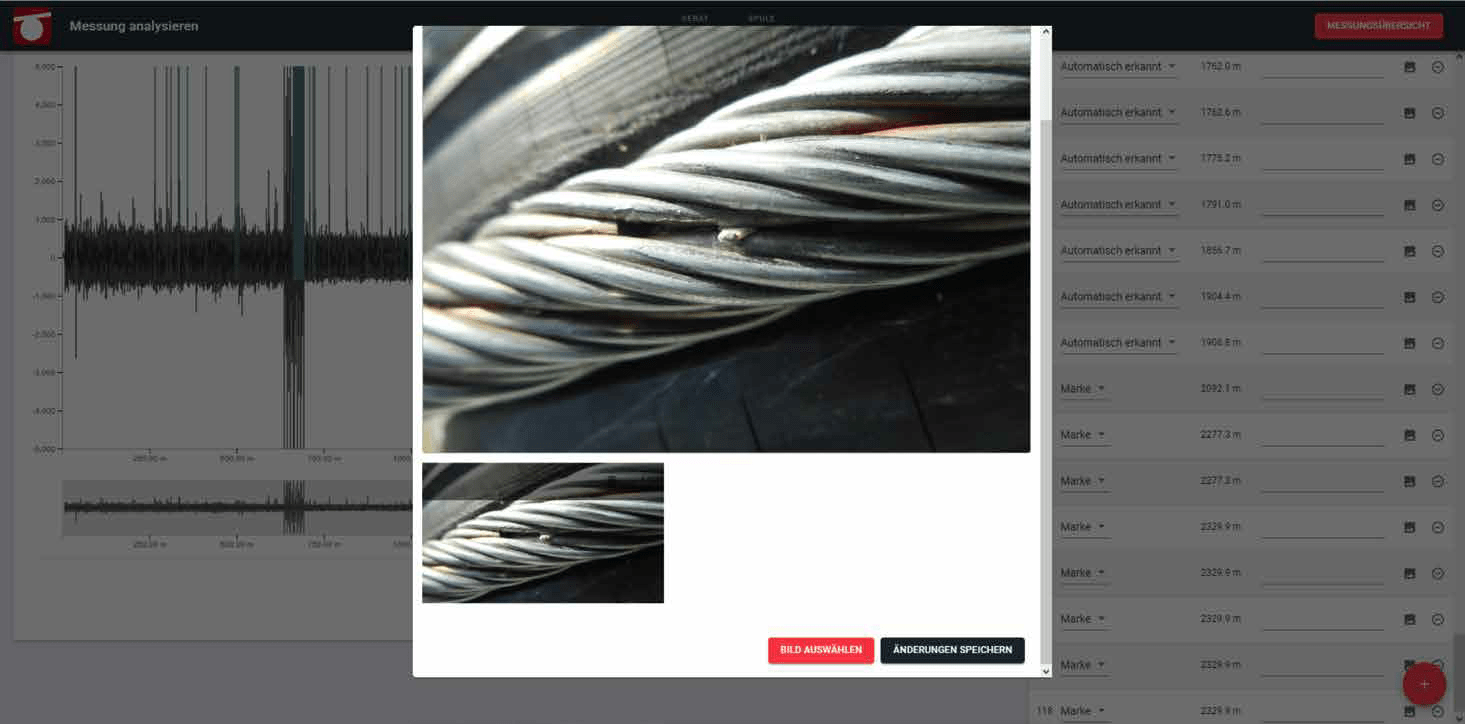

- In addition to manual measurement data, such as pitch length and diameter, the user can also add photos to the detected defects and link them directly to the corresponding defect.

- In addition to manual measurement data, such as pitch length and diameter, the user can also add photos to the detected defects and link them directly to the corresponding defect.

- Made in Germany

The production and distribution of the rope testers is carried out by ROPESYS GmbH under license ROTEC GmbH

The rope testers are available in the first sizes. Further standard and special sizes are being planned.

HERE you get an overview of the different devices and sizes

We will be pleased to answer your questions at any time. You can also find the answers to common questions in our FAQs.

As part of the Central Innovation Program for SMEs (ZIM) of the German Federation of Industrial Research Associations “Otto von Guericke” e.V. (AiF), the German Federal Ministry for Economic Affairs and Energy is funding ROTEC GmbH and innovative development of the novel rope testing system.

More information?

Here you can download the latest brochure of ROTEC GmbH

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information