Magnetic inline rope testing device for modern rope manufacturing.

In industrial rope production, quality is not determined at the point of dispatch or with the customer. It is created directly during the manufacturing process.

Therefore, the review is increasingly being integrated into the ongoing process.

The Inline magnetic rope testing device enables precisely this continuous monitoring.

Direct integration into the production line

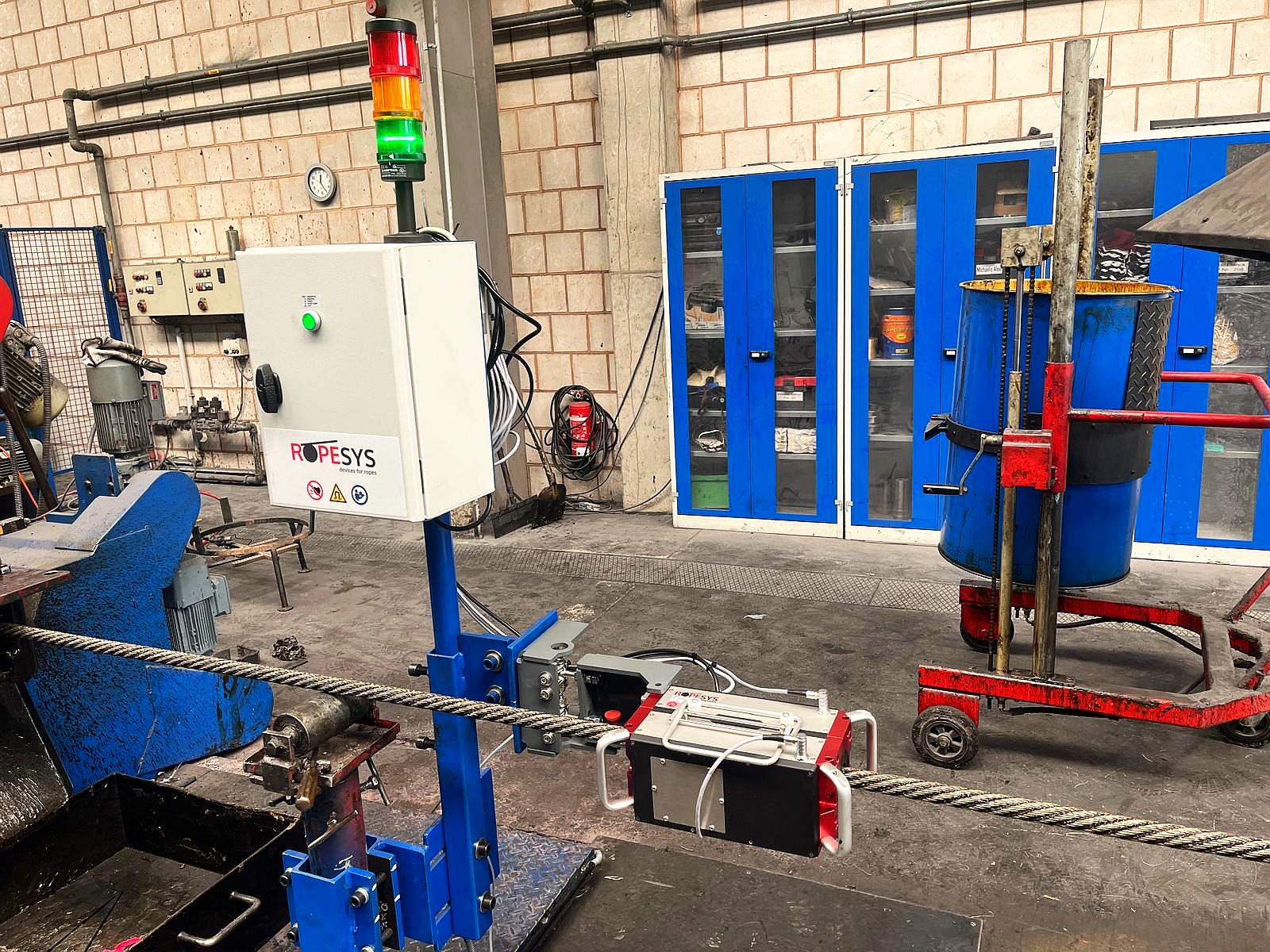

The testing system is specifically designed for inline process control in rope manufacturing. It is integrated directly into the production line of the stranding machine and is usually located directly after the stranding point.

This position allows the system to control each individual wire during manufacturing.

The magnetic test is performed in real time, even before the finished rope is wound onto the reel. Additional rewinding processes are completely eliminated.

Continuous real-time monitoring

All wires are monitored magnetically and continuously. Simultaneously, the system analyzes all measurement data in real time. As soon as an anomaly is detected, an immediate response is triggered.

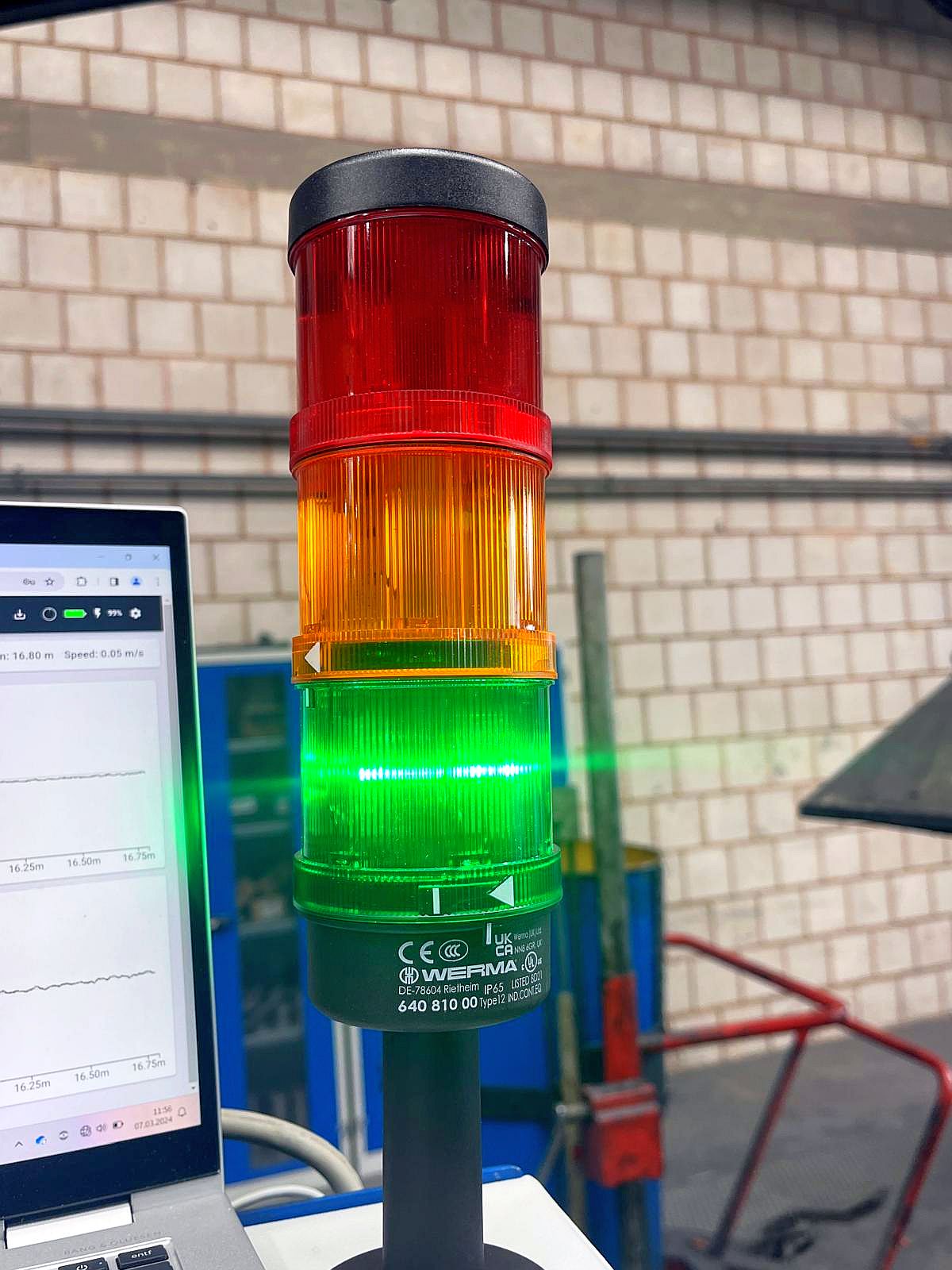

The signaling system can be flexibly configured. Depending on the requirements, the system provides information via a signal light, a display, or an audible alarm.

Additionally, the Ethernet connection enables remote viewing, so that those responsible can access the current data at any time, even remotely.

Active process control when limit values are exceeded

A key advantage lies in the direct connection to the stranding machine. If defined limits are exceeded, the system can intervene automatically. The machine can be slowed down or stopped if necessary.

This allows irregularities to be checked immediately, even before the rope is wound up or shipped. The flawless condition upon dispatch is thus verifiably documented.

Documented quality and long-term optimization

All measurement data is fully recorded and stored. This creates transparent documentation of production quality.

Manufacturers not only gain security in the ongoing process, but also a solid basis for later analyses and optimizations.

The Inline magnetic rope testing device is suitable for all types of steel strands and ropes. It can be flexibly integrated into existing production lines and helps manufacturers to consistently maintain and verifiably document their quality standards.

Inline testing as the key to efficiency

By integrating rope testing directly into the manufacturing process, defects are not only detected after the fact. They are identified immediately. This increases process reliability, efficiency, and cost-effectiveness equally.

For rope manufacturers, this means full control over every single strand throughout the entire production process – in real time and without an additional process step.

ROPESYS – Safety at the highest level. Made by engineers in Germany.

In the picture: